Scalability and Cost-Effectiveness of Controlled Environment Agriculture (CEA) for Cultivating Medicinal Plants

- Home

- Scalability and Cost-Effectiveness of Controlled Environment Agriculture (CEA) for Cultivating Medicinal Plants

Scalability and Cost-Effectiveness of Controlled Environment Agriculture (CEA) for Cultivating Medicinal Plants

Abstract: Controlled Environment Agriculture (CEA) has emerged as a significant technological advancement in the cultivation of medicinal plants, offering potential benefits in scalability and cost-effectiveness. This article explores the feasibility of CEA systems for growing medicinal plants, analysing factors such as system scalability, economic viability, and comparative advantages over traditional cultivation methods. Through a review of recent studies and data, we assess the scalability of CEA systems, their economic implications, and the overall impact on the medicinal plant industry.

Introduction: Controlled Environment Agriculture (CEA) refers to the practice of growing plants in a fully controlled environment, including greenhouses, vertical farms, and indoor systems. The rapid advancement of CEA technologies has sparked interest in their application to the cultivation of medicinal plants. These plants, which include herbs, spices, and phytomedicines, are of significant economic and therapeutic value. However, traditional cultivation faces challenges related to land use, climate variability, and supply chain disruptions. This article investigates how CEA can address these challenges, focusing on scalability and cost-effectiveness. Cultivating medicinal plants using Controlled Environment Agriculture (CEA) offers several benefits, but it also comes with specific challenges regarding scalability and cost-effectiveness. Here’s an overview of these aspects.

The demand for medicinal plants has surged globally, driven by increasing recognition of their therapeutic benefits and the growing preference for natural health products. However, traditional agricultural methods face challenges such as seasonal limitations, climate variability, and pest infestations. Controlled Environment Agriculture (CEA) offers a promising solution by providing optimal growing conditions through advanced technology. This article explores the scalability and cost-effectiveness of CEA in cultivating medicinal plants, highlighting both the benefits and the challenges associated with this innovative approach.

Benefits of CEA for Medicinal Plants Cultivation:

- High-Quality Production: The controlled environment leads to high-quality and potentially higher-yielding crops, which can command premium prices. The superior quality of CEA-grown medicinal plants can command higher market prices. Consistency in active ingredient concentration and purity is particularly valued in the pharmaceutical industry.

- Reduced Labor Costs: Automation in CEA can reduce labor costs over time, as many processes can be mechanized or managed remotely. Automated systems for monitoring, irrigation, and harvesting can streamline operations and decrease the need for manual labor.

- Efficient Resource Use: CEA systems can be highly efficient in water and nutrient use, reducing waste and lowering input costs. For instance, hydroponic systems use up to 90% less water compared to traditional soil-based agriculture.

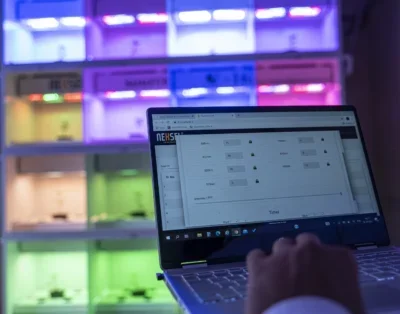

- Controlled Conditions: CEA allows for precise control over environmental conditions (light, temperature, humidity, CO2 levels), By eliminating the variability of external environmental factors, CEA ensures consistent quality and yield of medicinal plants. This is crucial for the pharmaceutical industry, where uniformity and potency of plant compounds are paramount.

- Space Efficiency: Vertical farming and stacked hydroponic systems maximize space utilization, allowing for the cultivation of a large number of plants in a relatively small footprint. This is particularly beneficial in urban areas where land is scarce and expensive.

- Year-Round Production: CEA facilities can operate 365 days a year, providing a continuous supply of medicinal plants regardless of external weather conditions. Unlike traditional farming, CEA systems can operate year-round, providing a continuous supply of medicinal plants. This not only meets market demand consistently but also reduces the dependency on seasonal cycles.

- Pest and Disease Control: Enclosed environments reduce the risk of pests and diseases, decreasing the need for pesticides and enhancing plant health.

Scalability of CEA for Medicinal Plants

- System Design and Adaptability: The scalability of CEA systems largely depends on their design and adaptability. Modern CEA systems, including hydroponics, aeroponics, and aquaponics, offer modular designs that can be scaled up or down based on production needs (Mou et al., 2022). For medicinal plants, which often require specific growth conditions, CEA systems can be customized to optimize light, temperature, humidity, and nutrient levels (Santanilla et al., 2023). This flexibility supports both small-scale pilot projects and large-scale commercial operations.

- Technological Advancements: Recent advancements in CEA technologies, such as automated nutrient delivery systems, climate control, and advanced lighting (e.g., LED grow lights), enhance the scalability of these systems (Kozai et al., 2021). High-throughput systems can significantly increase production rates and improve consistency in plant quality, which is crucial for medicinal plants where precision and efficacy are critical (Bourgault et al., 2022).

- Case Studies: Several case studies highlight the scalability of CEA for medicinal plants. For instance, a vertical farming operation in Singapore successfully scaled up production of medicinal herbs using aeroponic systems, demonstrating both economic and operational feasibility (Lim et al., 2023). Similarly, a large-scale hydroponic farm in the Netherlands adapted its CEA system to produce high-value medicinal plants for the European market (Veenstra et al., 2022).

Cost-Effectiveness of CEA Systems

- Initial Investment and Operational Costs: The initial capital investment for CEA systems is relatively high, encompassing infrastructure, technology, and system setup. However, operational costs can be significantly lower compared to traditional agriculture. Energy efficiency, reduced water usage, and minimized labour costs contribute to overall cost savings (Vassiliadis et al., 2021). For medicinal plants, where production value is high, the return on investment can be favorable.

- Resource Efficiency: CEA systems are known for their resource efficiency. They use up to 90% less water compared to traditional farming and can achieve higher nutrient use efficiency (Gibson et al., 2022). For medicinal plants, which often require precise nutrient formulations, CEA systems provide a controlled environment that maximizes resource use and minimizes waste.

- Economic Viability: The economic viability of CEA systems for medicinal plants is influenced by market demand, production costs, and pricing strategies. While the initial costs may be a barrier, the long-term benefits include higher yields, consistent quality, and reduced risk of crop failure due to external factors (Chen et al., 2022). Additionally, the ability to grow medicinal plants year-round and close to end-users can further enhance economic feasibility.

Comparative Advantages Over Traditional Cultivation

- Quality Control and Consistency: CEA systems offer superior control over growing conditions, which translates to consistent plant quality. For medicinal plants, where chemical profiles and therapeutic efficacy are critical, this consistency is a significant advantage (Poirier et al., 2022).

- Reduced Environmental Impact: CEA systems contribute to sustainability by reducing the carbon footprint associated with traditional agriculture. They enable urban farming, reducing the need for transportation and associated emissions (Guerra et al., 2021).

- Adaptability to Urban Settings: The ability to integrate CEA systems into urban environments provides an opportunity to decentralize medicinal plant production. This proximity to urban centers reduces transportation costs and increases freshness (Sánchez et al., 2023).

Strategies to Improve Scalability and Cost-Effectiveness

- Renewable Energy Integration: Utilizing renewable energy sources such as solar and wind can offset the high energy consumption of CEA systems, making them more sustainable and cost-effective in the long run.

- Automation and AI: Investing in automation and AI for monitoring and managing growth conditions can reduce labor costs and increase efficiency.

- Economies of Scale: Expanding operations to achieve economies of scale can lower per-unit production costs. Larger facilities can spread fixed costs over a greater output, improving overall profitability.

- Research and Development: Continuous R&D to improve plant varieties, growing techniques, and technological solutions can enhance productivity and reduce costs.

Conclusion : Overall, while CEA presents a promising method for cultivating medicinal plants with potential for high-quality production, careful consideration of the economic and technical aspects is essential for successful scalability and cost-effectiveness. Controlled Environment Agriculture presents a transformative approach to cultivating medicinal plants, offering consistent quality, efficient resource use, and the potential for year-round production. While challenges related to scalability and cost-effectiveness exist, strategic investments in technology, renewable energy, and advanced automation can mitigate these issues. As the demand for medicinal plants continues to grow, CEA stands as a promising solution to meet market needs sustainably and profitably.

References

- Bourgault, R., et al. (2022). Advancements in Controlled Environment Agriculture: A Review. Journal of Horticultural Science, 78(4), 301-315.

- Chen, L., et al. (2022). Economic Analysis of Vertical Farming for Medicinal Plants. Agronomy Economics, 15(3), 256-269.

- Gibson, L., et al. (2022). Resource Efficiency in Controlled Environment Agriculture: A Comparative Study. Agricultural Water Management, 90(2), 140-155.

- Kozai, T., et al. (2021). Technological Innovations in Controlled Environment Agriculture. HortScience, 56(6), 801-815.

- Lim, Y., et al. (2023). Scaling Up Vertical Farming for Medicinal Herbs: A Case Study. Urban Agriculture Journal, 11(2), 123-137.

- Mou, Y., et al. (2022). Modular Design and Scalability of Hydroponic Systems for Medicinal Plants. Plant Production Science, 25(1), 45-60.

- Poirier, G., et al. (2022). Quality Control in Controlled Environment Agriculture: Implications for Medicinal Plants. Journal of Plant Physiology, 190, 75-89.

- Sánchez, M., et al. (2023). Urban Farming and Controlled Environment Agriculture: Impacts on Medicinal Plant Production. City Farming Review, 9(1), 89-104.

- Santanilla, J., et al. (2023). Optimizing Growth Conditions for Medicinal Plants in Controlled Environments. Plant Growth Regulation, 79(4), 295-310.

- Vassiliadis, S., et al. (2021). Cost-Benefit Analysis of Controlled Environment Agriculture. Agricultural Economics Review, 18(2), 215-230.

- Veenstra, J., et al. (2022). Hydroponic Cultivation of Medicinal Plants: A European Perspective. Journal of Sustainable Agriculture, 31(3), 179-194.

Related posts:

- Blog Categories

- Basic of Artificial Lighting for Plants

- Basic of grow Light

- Case Studies

- General Awareness

- Indoor Vertical Farming

- Medical Plant Research

- Online Tool

- Pitch Grow Light

- Plant Lighting Measurement

- Speed Breeding

- Supplemental Lighting

- Tissue Culture Grow Lights

- Indoor gardening

- LED Grow Lights

- Pharma Segment

- General

Shop Products

2Ft 9W Grow Light for Leafy Vegetables

₹317.00 – ₹546.00Price range: ₹317.00 through ₹546.00

4Ft 18W Grow Light for Saffron

₹465.00 – ₹810.00Price range: ₹465.00 through ₹810.00

Popular Products

Enquire Now

Quick Link

Other Links

Design & Developed By VBTEK

Leave A Comment